1. Scrap

Scrap is defined as recycled material which is generated during a manufacturing process. Companies try to reduce the amount of scrap that is produced but it is not possible to eliminate these. Scrap is either used in subsequent production runs or it can be sold to other companies which recycle them or, companies may need to pay to dispose of.

A metals company might not be able to use the metal shavings from a single production run but overtime the metal shavings accumulate and can be used in a production run. The metal shavings can also be sent to a processor in the scrap metal industry for further processing.

Image 1: Metal Shavings

Another example of scrap might be the resin which is used during plastic extrusion process. The scrap from the resin will be collected and used again in subsequent orders or it could be sold to a recycling company. The company might substitute the virgin material with the scrap, regrind or recycled material.

Image 2: Resin Pellets

In a meat processing plant, trimmings might be the scrap which are generated after other cuts are made. The trimmings can be used in another process, used for animal feed, or sold to another food manufacturer.

Image 3: Meat Trimmings

D365 Finance and Operations allows both discrete and process companies to define scrap on Bills of Materials (BOM)/Formulas and Routes to allow organizations to plan for additional raw material quantities that would be required for a production run. This document discusses the differences between setting up scrap on Bill of Materials (BOM)/Formulas vs. a Route.

2. BOM/Formula Scrap Calculations

Path: Product information management/Bills of materials and formulas/Bills of materials or

Path: Product information management/Bills of materials and formulas/Formulas

Note: We will use a formula defined in Contoso Process Industries (USPI) for Illustration purposes

Bill of Materials/Formulas in D365 allows users to define 2 different types of scrap

1. Constant Scrap

2. Variable Scrap

Image 4: Formula Details for item P4000

2.1. Constant Scrap

The Quantity of material used during the initial setup and startup of a line is called as the Constant scrap. This is the amount of material that is not dependent on the quantity produced and will always be scraped during the machine start-up and calibration for this item.

Formula for Item P4000, Name: Polypropylene Pellet

Image 5: Constant Scrap on Formula Line M4004

Constant Scrap = 100.00

Create a production order for Item P4000 (Polypropylene Pellet) for 10,000 lbs. and estimate it

Quantity required for M4004 Polypropylene as = 10*867 +100 = 8770 lbs.

The estimated quantity for M4004 shows 8770 lbs.

Image 6: Formula Lines on a Production order with Estimated Quantities

2.2. Variable Scrap

This is the amount of material that is discarded during the production run and as the name suggests it varies based on the quantity produced. This field is defined as a percentage and the raw material requirement is increased by the quantity specified in this field.

Formula for Item P4000, Name: Polypropylene Pellet

Image 7: Variable Scrap on Formula Line M4004

In this case ‘Variable Scrap’= 10.00

Create a production order for Item P4000 (Polypropylene Pellet) for 10,000 lbs. and estimate it

Quantity Required for M4004 = 10*867+ (10*867) *(10/100)= 9537 lbs.

The estimated quantity for M4004 shows 9537 lbs.

Image 8: Formula Lines on a Production order with Estimated Quantities

2.3. Constant and Variable Scrap

Formula for Item P4000, Name: Polypropylene Pellet

Image 9: Constant and Variable Scrap on Formula Line M4004

Create a production order for Item P4000 (Polypropylene Pellet) for 10,000 lbs. and estimate it

Quantity Required for M4004 = 10*867+ (10*867) *(10/100) + 100= 9637 lbs.

The estimated quantity for M4004 shows 9637 lbs.

Image 10: Formula Lines on a Production order with Estimated Quantities

Note: When the cost roll up is done for the BOM/Formula the scrap quantities are included in the calculations

3. Route Scrap Calculations

The route scrap is used when an organization wants to specify the scrap by operation. Each operation can have a different scrap percentage, and this tells the system the additional quantity that must be produced because of the scrap on that operation. The calculated hours on the operation are also affected by the scrap percentage specified.

Path: Production control/Operations/All routes

Click on Route details

Route 000003 is associated with Item P4000 (Polypropylene Pellet)

Image 11: Route details form

- The scrap percentage by default is 0.00

- The Accumulated value by default is 1.00

The accumulated value is updated when the scrap value changes, and it drives the component quantity requirements to account for the inefficiencies in the operation.

3.1 Calculation of Accumulated Value

Case 1: Change the Scrap percentage of operation 10 to 10 %

Image 12: Scrap Percentage on Operation 10

When the scrap percentage is changed the ‘Accumulated’ does not change automatically.

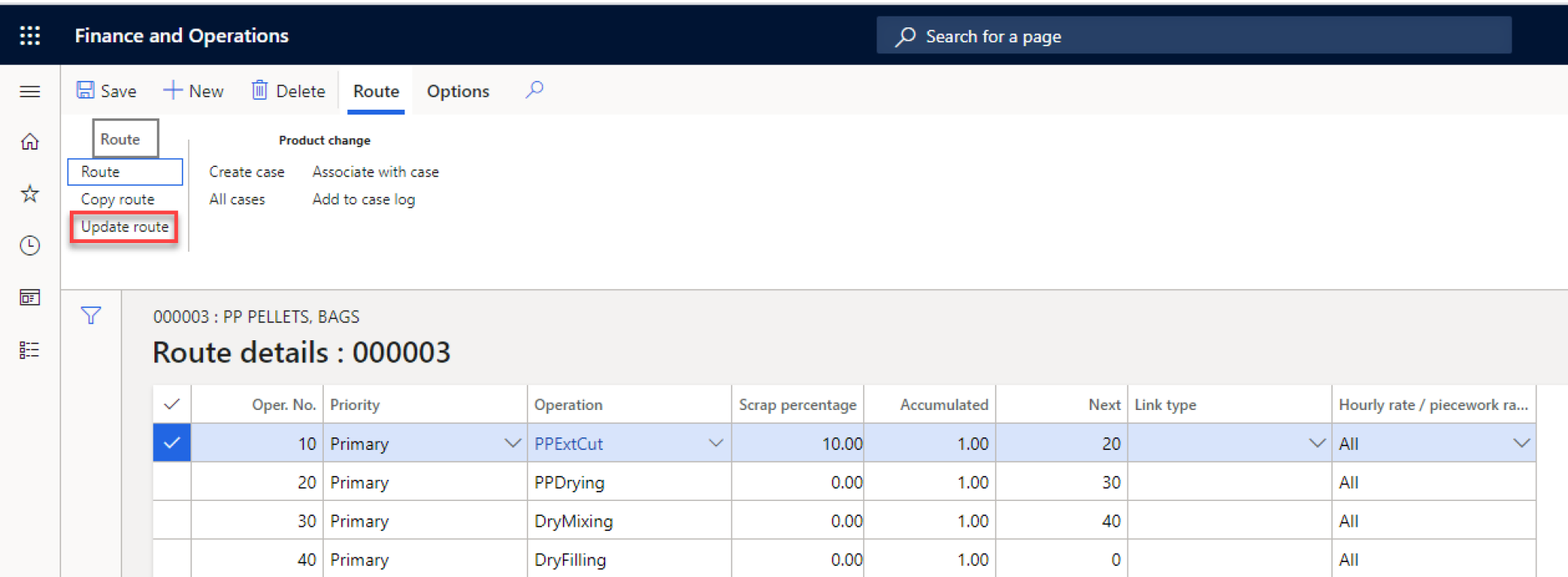

The value is calculated when a user either closes the form or clicks on ‘Route/Update route’ on the activity tab as shown below

Image 13: Update route

The Accumulated field now shows a value of 1.11

Image 14: Calculated Accumulated Value on Operation 10

If we look at the calculation for Accumulated we find:

Case 2: Define the scrap percentage of 10 on operation 10 and operation 30

Image 15: Scrap Percentage on Operation 10 and 30

Click on Route/Update route

The update accumulated values are shown below

Image 16: Calculated Accumulated Value on Operation 10, 20 and 30

The system calculates the values from the last operation to the first one.

3.2. Association of Operation to a Formula Item

Formula details section allows users to specify the operation in which each item is consumed

Image 17: Association of Operations with Formula Lines

- In the above example the first 2 items are associated with operation 10. The accumulated value specified on operation 10 in the previous section will be used to calculate the amount of the component M4004 and M4005 needed for the production.

- If an operation is not specified on the Formula/BOM lines, then the system considers all materials will be required for operation 10.

3.3. Production Order using route scrap

Create a production order for Item P4000 (Polypropylene Pellet) for 10,000 lbs. and estimate it

Only operation 10 has a scrap percentage specified on it

Image 18: Calculated Accumulated Value on Operation 10

Formula

The system calculates a value of 9633.33 for item M4004 and 1077.78 for item M4005

Image 19: Estimated quantities of items M4004 and M4005

Calculation of estimated quantity for M4004 = (10000) *(867/1000) *1.11111 = 96333.33

Calculation of estimated quantity for M4005 = 10000(97/1000) *1.11111= 1077.78

In this example because of inefficiencies in operation 10, you need extra quantities of items M4004 and M4005. Other items which are used on subsequent operations are not affected by this.

Route

Schedule the order

Image 20: Scheduled Jobs for the Production Order

Operation 10 is scheduled from 7:30 AM to 9: 10 AM = 100 Minutes

The standard route was specified at 45 mins for 5000 units

For 10,000 units = 90 mins

Taking the Accumulated(scrap) into account = 90 *1.11111= 99.9999 =100 minutes

In conclusion the scrap percentages can be specified both on BOM/Formulas or Routes. Where you specify will depend on the business needs of your organization.